for our marketers ”

Digital Printing

UV Printing

Embroidery

Debossing and Embossing

Digital Printing

Digital printing or full-color printing makes the use of laser or inkjet printers to print out complex and elaborate designs in a flash! It is the best printing method for multicolored designs, artworks, and logos. This technique requires one to upload the image or logo on digital appliances like computers, and the picture is directly printed on the surface of the material.

The realm of digital printing is ever-increasing. It provides several advantages such as completion of the job way quicker. Also, it is effortless to operate and is, consequently, very popular.

UV Printing

UV printing comes under the umbrella of digital printing. It uses a special kind of ink that is cured quickly by exposing it to intense ultraviolet radiation. This fast printing process allows high-quality and clear images on a wide variety of surfaces. In addition, UV ink is also more resistant to corrosion and, therefore, more long-lasting.

UV printing can print on a lot of different surfaces.: fabric, glass, wood, plastic, acrylic, wood, aluminum, and more.

Embroidery

Embroidery is the art of sewing designs using needles, yarns, and threads. This method is an age-old technique that requires a lot of staffing if done manually. But not anymore! Modern technology has made it easy for brands to stitch designs and logos on apparel using embroidery machines. Just like digital printing, the design is uploaded on a computer. This design can be any custom or digitally made design on any embroidery software. After this, an embroidery machine stitches or embroiders the fabric one color at a time. From household items such as carpets, quilts, draperies to merchandise and clothing, one can do embroidery on anything. Thus, computerized embroidery machines are indeed a boon.

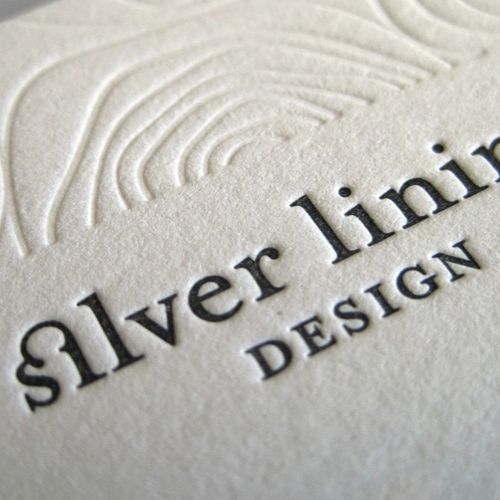

Debossing and Embossing

Three-dimensional and textured designs are extremely trendy nowadays. One can achieve this kind of superb printing through debossing or embossing.

Embossing gives the design a raised-up effect, while debossing gives an indented or sunken design. Both ways help make the logo or design more eye-catching and prominent than the rest of the surface.

Two metal dies, one raised and one recessed, are used in this method of printing. These dies fit perfectly with each other and create a textural contrast when pressed onto the material. This technique is mainly used for paper, padfolios, leather goodies, etc.

Epoxy Dome

Hot Stamping

Laser Engraving

Offset Printing

Epoxy Dome

As the name suggests, epoxy dome makes the use of epoxy or clear plastic to form a protective coating or crown that can be added or affixed to any logo or design. By doing this, the product’s look is elevated several notches because of the high-shine and glossy finish that epoxy provides.

Not many people know about this unique technique or the many advantages that come with it. Printing inks and design paints are usually susceptible to scratching, scraping, and fading over time. Epoxy domes are known to make the design very long-lasting, durable, and high-quality.

Hot Stamping

Hot Stamping or foil printing is a technique to apply metallic or pigmented foil onto the surface of materials using heat. The foil is placed beneath a hot metal or silicon die and then pressed onto the object, preferably leather or paper.

Hot stamping gives the print a stunning look by incorporating the elements of shine and luster. The image can also be made holographic or three-dimensional with the appropriate kind of foil.

Laser Engraving

It is quite hard to print on rigid and slippery surfaces that do not hold ink well. In such cases, laser engraving is the way to go. It can be used for various materials like stainless steel, wooden surfaces, knives, glassware, etc. Instead of an engraving tool or colored ink, laser beams are used in this method of printing.

A laser engraving machine shoots a laser beam on the surface of the object. This laser beam is highly focused and hot enough to vaporize the material, engraving the design on the surface by creating a cavity.

Laser Etching melts the material wherever the hot beam falls. The melted material bubbles or foams up to create a raised design. Although not colorful, these designs are permanent and durable.

Offset Printing

From newspapers to books, magazines, canvases, etc., you will be surprised to know that several objects around us are printed upon using this printing method. In offset printing, designs printed on metal plates are offset or transferred to the material using a rubber roller. The rubber roller is flexible enough to adhere to the material’s surface and give a clean and solid print.

Offset printing results in high-resolution prints that are sharp and crisp. Although time-consuming, this technique is highly economical, and the equipment requires little maintenance. It is the best method for bulk printing as the setup cost is relatively high.

Pad Printing

Decorating Firing

Abrasive Blasting

Silk Screen Printing

Pad Printing

Pad printing, also known as tampography, is used to print a two-dimensional design on three-dimensional surfaces. It accurately prints every design even though it can be comparatively slower than other methods.

Three-dimensional surfaces such as sports gears, stationery, toys, medical equipment, etc., are often small and are hard to print on. In pad printing, a silicon pad is used to transfer the ink onto the object’s surface. The silicone pad is flexible and versatile enough to hug any shape like a sphere, cylindrical, concave, and convex surfaces.

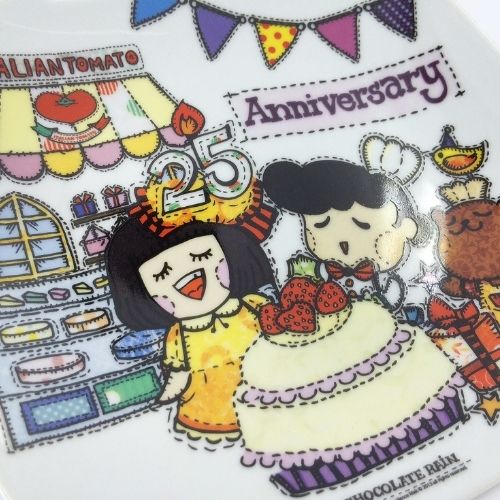

Decorating Firing

Pottery made out of clay is decorated using this technique of decorative firing. Usually done under very high-temperature conditions available only in kilns, firing alters the physical and chemical composition of the material.

The atmosphere of the kiln may also change the appearance of the clayware. After this, the object is glazed, followed by another round of firing called “glaze firing”. It melts the glaze and makes it adhere to the surface permanently, giving a shiny and polished finish that is long-lasting and permanent.

Abrasive Blasting

Abrasive blasting, more commonly known as sandblasting, is a destructive processing method for the surface of the material. It uses fine abrasive sand particles to impact the surface of the material, causing the surface to produce granular depressions to form fog or erosion. It can achieve the effects of removing rust, burrs, de-oxidizing layer, stress treatment, friction coefficient adjustment, precision adjustment, high adhesion, beautification, atomization, matting, and improving the surface finish of the material.

Silk Screen Printing

You have probably come across viral videos online of screen printing, where ink is forced onto the material through a custom-made mesh screen. Screen printing is also called silkscreen printing. As in ancient times, silk screens were used instead of synthetic threads that are used nowadays. A blocking stencil prevents color deposition in other spaces by making it impermeable to the ink.

Only a single color can be printed on one layer, while multi-colored prints require several layers of screen printing with different stencils. This technique of printing is highly versatile as it can be used for a wide variety of materials. What makes screen printing a prevalent method of printing is its cost-effectiveness and easy availability.

Thermal Transfer Printing

Woven Label

Thermal Transfer Printing

Woven Label

Thermal Transfer Printing

Thermal Transfer Printing or heat transfer printing is so-called, as it uses heat to transfer or iron-on the image onto the material. One must paste the image to be transferred on a wax sheet or Teflon-coated paper. This way, when the wax melts, the image is secured onto the surface of the substrate. Another way is to layer wax dye to create the desired image.

Thermal Transfer Printing comes with several advantages. Primarily used to imprint artworks or pictures onto apparel and other items, thermal transfer printing is an excellent method to make the print long-lasting and resistant to heat and water. This method can incorporate vividly bright and high-resolution images on the objects.

Woven Label

Woven labels and tags are an excellent way for brands to incorporate their brand name and some additional information on their products. This method increases the authenticity of the product and helps to uptick the class and beauty of the material. Usually, we use polyester threads to weave in the desired design on the label using a loom. Then, the finished label is further woven onto the products. This technique ensures durability and allows incorporating colors from a wide range of color palettes for creating intricate designs.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Sign up Facebook

Sign up Facebook

Sign up Google

Sign up Google